Plumbing insulation products are essential for maintaining the efficiency and longevity of any plumbing system. From pipes to valves, insulation plays a crucial role in preventing heat loss, reducing noise, and protecting against condensation.

In this comprehensive guide, we will explore the various types of plumbing insulation products available, their benefits and applications, and the techniques for proper installation. Whether you’re a professional plumber or a DIY enthusiast, this guide will provide you with the knowledge and insights you need to make informed decisions about plumbing insulation.

Product Overview

Plumbing insulation products play a crucial role in maintaining optimal water temperatures, preventing heat loss, and minimizing energy consumption in plumbing systems. They come in various types, each with unique benefits and applications.

The choice of insulation product depends on factors such as the type of plumbing system, operating temperature, and budget. To help you make an informed decision, here’s an overview of the most common types of plumbing insulation products:

Types of Insulation Products

- Fiberglass Insulation:Fiberglass insulation is made from glass fibers and is available in batts, rolls, and loose-fill form. It offers good thermal resistance, is fire-resistant, and relatively inexpensive.

- Foam Insulation:Foam insulation is made from expanded polystyrene or polyurethane and comes in sheets or spray-on form. It provides excellent thermal insulation, is moisture-resistant, and easy to install.

- Rubber Insulation:Rubber insulation is made from synthetic or natural rubber and is available in sheets or tubes. It offers excellent thermal insulation, is highly flexible, and resistant to moisture and chemicals.

- Mineral Wool Insulation:Mineral wool insulation is made from volcanic rock or slag and is available in batts, rolls, and loose-fill form. It provides good thermal and acoustic insulation, is fire-resistant, and moisture-resistant.

Comparison of Insulation Products

To help you compare the different types of insulation products, here’s a table summarizing their key characteristics:

| Insulation Type | R-Value | Cost | Ease of Installation |

|---|---|---|---|

| Fiberglass Insulation | 2.2

|

$0.25

|

Easy |

| Foam Insulation | 3.5

|

$0.50

|

Moderate |

| Rubber Insulation | 3.0

|

$0.75

|

Difficult |

| Mineral Wool Insulation | 2.5

|

$0.35

|

Easy |

Insulation Materials

Plumbing insulation products employ a variety of materials, each with its distinct characteristics. Understanding these materials is crucial for selecting the most suitable insulation for specific plumbing applications.

The most common insulation materials are fiberglass, foam, and rubber. Each material offers unique advantages and disadvantages, which we will explore in the following sections.

Fiberglass

Fiberglass insulation is made from fine glass fibers, providing excellent thermal resistance. It is commonly available in batts, rolls, and loose-fill forms. Fiberglass is relatively inexpensive and easy to install.

However, fiberglass insulation can be irritating to the skin and respiratory system. It also absorbs moisture, reducing its insulating effectiveness. Additionally, fiberglass insulation may settle over time, reducing its thermal performance.

Foam

Foam insulation is made from plastic or rubber, providing superior moisture resistance compared to fiberglass. It is available in various forms, including sheets, boards, and spray foam.

Foam insulation is lightweight, easy to install, and highly durable. It also provides excellent thermal resistance. However, foam insulation can be more expensive than fiberglass. Additionally, some foam insulation materials may release harmful chemicals.

Rubber

Rubber insulation is made from natural or synthetic rubber, providing excellent moisture resistance and flexibility. It is commonly used for insulating pipes and valves in outdoor applications.

Rubber insulation is durable, resistant to chemicals, and has a high thermal resistance. However, it is more expensive than fiberglass and foam insulation. Additionally, rubber insulation can be difficult to install and may deteriorate over time.

Comparison of Insulation Materials

| Material | Thermal Conductivity (W/m·K) | Durability | Moisture Resistance |

|---|---|---|---|

| Fiberglass | 0.040-0.050 | Moderate | Poor |

| Foam | 0.025-0.035 | Excellent | Good |

| Rubber | 0.035-0.045 | Good | Excellent |

Installation Techniques: Plumbing Insulation Products

Installing plumbing insulation products is crucial to ensure optimal performance and energy efficiency. Various techniques are available, each suited for specific applications. Understanding these techniques and following proper installation procedures is essential for a successful outcome.

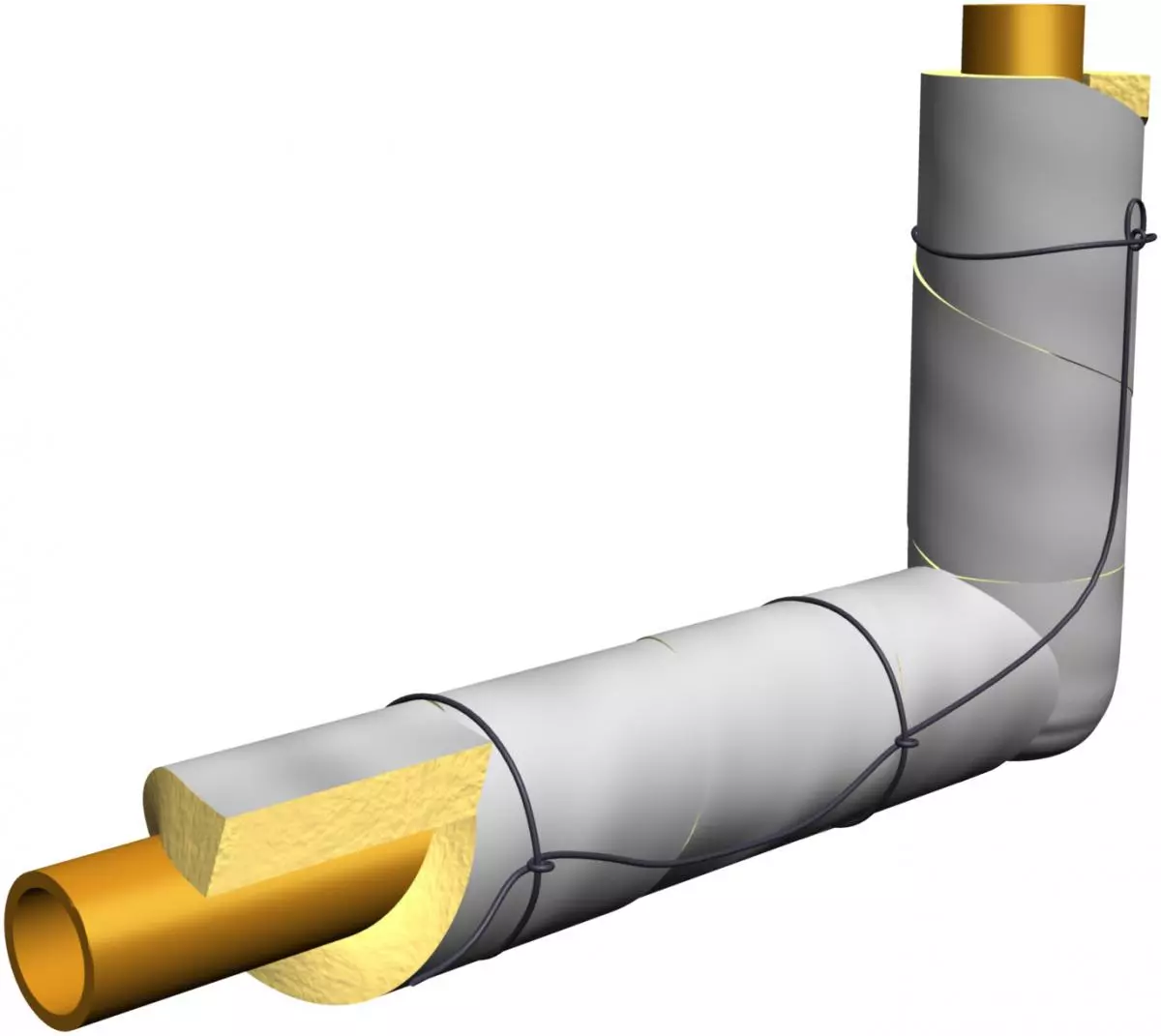

Installing Insulation on Pipes

- Measure and Cut:Determine the length of pipe to be insulated and cut the insulation accordingly.

- Apply Adhesive:Apply adhesive to the inner surface of the insulation, ensuring even distribution.

- Slide Insulation:Carefully slide the insulation over the pipe, aligning it properly.

- Secure Insulation:Use insulation tape or straps to secure the insulation firmly in place.

Installing Insulation on Valves and Fittings

- Choose Insulation Type:Select insulation specifically designed for valves and fittings.

- Cut Insulation:Cut the insulation to fit the shape of the valve or fitting.

- Apply Adhesive:Apply adhesive to the insulation and attach it to the surface.

- Cover Exposed Areas:Ensure all exposed areas are adequately covered to prevent heat loss.

Tips for Ensuring Proper Installation

- Use the Right Insulation:Choose insulation products appropriate for the application and environment.

- Fit Snugly:Ensure the insulation fits tightly around pipes and fittings to minimize air gaps.

- Seal Joints:Use insulation tape or sealant to seal any joints or overlaps in the insulation.

- Avoid Compression:Do not compress the insulation, as it can reduce its effectiveness.

Video Demonstration

For a visual guide to installing plumbing insulation products, refer to the following video demonstration:

- [Link to video demonstration]

Energy Efficiency

Insulation plays a vital role in enhancing the energy efficiency of plumbing systems. By reducing heat loss through pipes and water heaters, insulation minimizes energy consumption and lowers utility bills.

In water heaters, insulation acts as a barrier between the hot water tank and the surrounding environment. This prevents heat from escaping, reducing the amount of energy required to maintain the desired water temperature. As a result, water heaters insulated with high-quality materials consume less energy and operate more efficiently.

Case Study, Plumbing insulation products

A study conducted by the U.S. Department of Energy found that insulating a 50-gallon water heater with a 2-inch thick blanket of insulation can save approximately 450 kilowatt-hours of electricity or 380 cubic feet of natural gas per year. This translates to a significant reduction in energy consumption and cost savings for homeowners and businesses.

Closure

In conclusion, plumbing insulation products are an indispensable part of any well-maintained plumbing system. By choosing the right type of insulation and installing it correctly, you can improve energy efficiency, reduce noise levels, and protect your pipes from damage. Whether you’re dealing with hot or cold water pipes, indoor or outdoor plumbing, there is an insulation solution that meets your specific needs.