Plumbing backflow preventers are essential devices that safeguard your water system from contamination. They play a crucial role in preventing potentially hazardous backflow, ensuring the purity of your drinking water. This comprehensive guide will delve into the world of plumbing backflow preventers, exploring their purpose, types, installation, maintenance, and regulations.

Plumbing Backflow Preventers

Backflow is the undesirable reversal of the flow of water or other fluids in a plumbing system. It can occur when there is a sudden drop in water pressure, creating a vacuum that sucks water back into the system from an external source.

This can lead to contamination of the water supply and pose serious health risks.

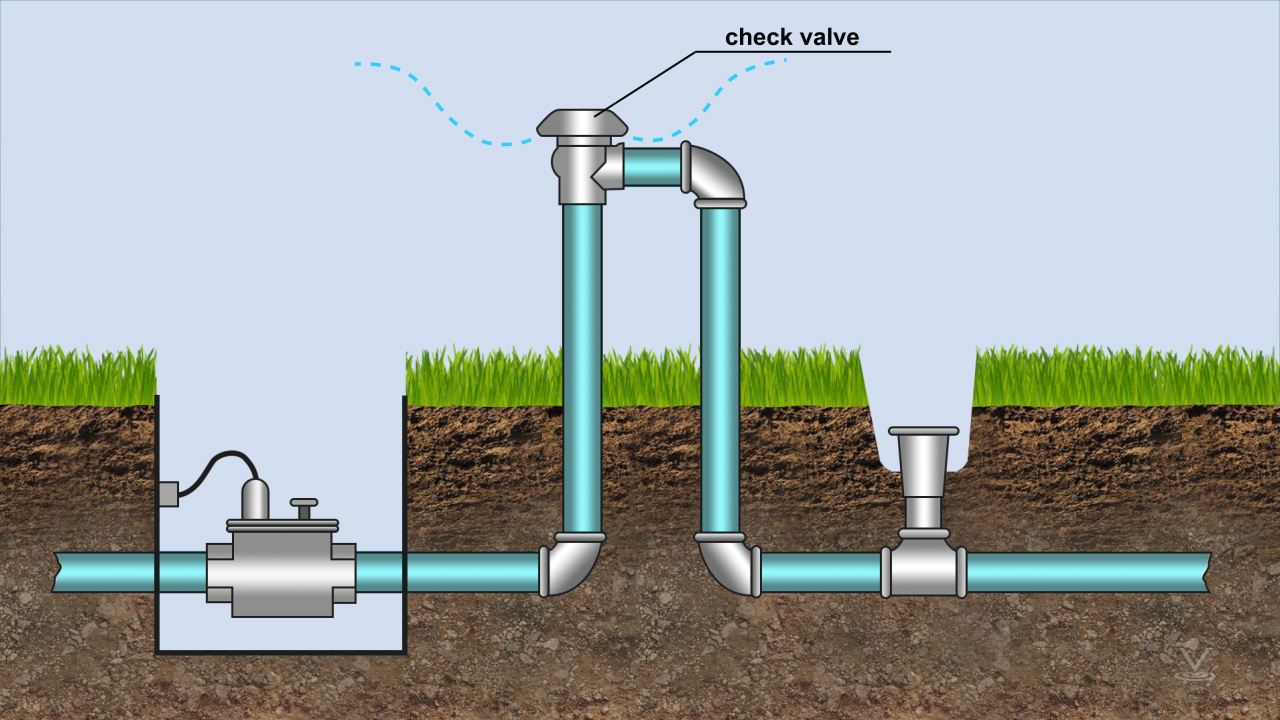

Plumbing backflow preventers are devices installed in plumbing systems to prevent backflow from occurring. They work by creating a physical barrier that prevents water from flowing back into the system. There are various types of backflow preventers, each designed for specific applications and levels of backflow risk.

Importance of Backflow Prevention in Plumbing Systems

Backflow prevention is crucial in plumbing systems to ensure the safety and quality of the water supply. By preventing backflow, plumbing backflow preventers protect against:

- Contamination of the water supply with harmful substances, such as sewage, chemicals, or bacteria.

- Cross-contamination between different water sources, such as potable water and non-potable water.

- Damage to plumbing fixtures and appliances due to backflow pressure.

Types of Plumbing Backflow Preventers

Backflow preventers are crucial devices that safeguard drinking water systems from contamination by preventing the reversal of water flow. These devices come in various types, each designed for specific applications and featuring unique working principles.

Atmospheric Vacuum Breakers (AVBs)

AVBs are commonly used in outdoor applications, such as hose bibbs and irrigation systems. They work by creating a vacuum break in the water line when water flow ceases. This vacuum prevents backflow by drawing air into the device, creating a physical barrier between the potable water supply and the potential source of contamination.

Double Check Valve Assemblies (DCVAs), Plumbing backflow preventer

DCVAs consist of two independent check valves installed in series. These valves allow water to flow in one direction only and automatically close in the event of backflow. DCVAs are typically used in commercial and industrial applications where the risk of backflow is high, such as in medical facilities and food processing plants.

Reduced Pressure Zone Assemblies (RPZAs)

RPZAs are the most comprehensive type of backflow preventer, offering the highest level of protection against backflow. They feature two check valves and a pressure-reducing chamber. When backflow occurs, the pressure differential between the upstream and downstream sides of the RPZA causes the check valves to close and the pressure-reducing chamber to flood, creating a physical barrier against contamination.

Comparison of Backflow Preventer Types

| Feature | AVB | DCVA | RPZA |

|---|---|---|---|

| Application | Outdoor | Commercial/Industrial | High-risk applications |

| Working Principle | Vacuum break | Double check valves | Pressure-reducing chamber |

| Protection Level | Low | Medium | High |

| Cost | Low | Medium | High |

| Maintenance | Low | Medium | High |

Installation and Maintenance of Backflow Preventers

Backflow preventers are essential devices that safeguard potable water supplies from contamination. Proper installation and regular maintenance are crucial to ensure their effectiveness.

Installing a backflow preventer requires careful attention to the manufacturer’s instructions. Generally, the process involves:

- Shutting off the water supply and draining the system.

- Cutting the pipe at the designated installation point.

- Connecting the backflow preventer to the pipe, ensuring the flow direction is correct.

- Tightening the connections and turning on the water supply.

Regular maintenance is equally important. Backflow preventers should be tested annually by a qualified plumber to verify their functionality. They should also be inspected for any signs of damage or corrosion. If any issues are detected, the device should be repaired or replaced promptly.

Consequences of improper installation or maintenance can be severe. Contaminated water can lead to health hazards, while cross-connections can compromise the entire water supply system. Therefore, it is essential to ensure that backflow preventers are installed and maintained correctly to safeguard public health and prevent costly repairs.

Regulations and Standards for Backflow Preventers

Regulations and standards play a crucial role in ensuring the proper installation and maintenance of backflow preventers. These measures are in place to safeguard public health and prevent contamination of water sources.

Certification and Testing

Backflow preventers must meet specific standards and certifications to ensure their effectiveness. Independent testing organizations evaluate these devices to verify their compliance with industry guidelines. Certification indicates that the backflow preventer has undergone rigorous testing and meets the required performance criteria.

Potential Consequences of Non-Compliance

Non-compliance with backflow preventer regulations can lead to severe consequences. Contaminated water can pose serious health risks to individuals and communities. Failure to adhere to standards can result in fines, legal penalties, and potential liability for property damage or injuries.

Last Point

By understanding the significance of plumbing backflow preventers and implementing proper installation and maintenance practices, you can ensure the safety and integrity of your water supply. Remember, these devices are not just a legal requirement; they are an investment in the well-being of your family and community.