Hornady lock n load case feeder – Introducing the Hornady Lock-N-Load Case Feeder, a game-changer in the world of reloading. Its innovative design and intuitive operation make it the perfect companion for any reloader seeking precision and efficiency.

This ingenious device seamlessly automates the case feeding process, saving you countless hours and reducing strain on your hands. Its versatility extends to a wide range of reloading presses and cartridges, ensuring compatibility with your existing setup.

Hornady Lock-N-Load Case Feeder Overview

The Hornady Lock-N-Load Case Feeder is an automated case feeding system designed to streamline the reloading process. It is compatible with most popular reloading presses and offers a range of features to enhance efficiency and convenience.

Key Features and Benefits, Hornady lock n load case feeder

The Hornady Lock-N-Load Case Feeder features several key benefits that make it an ideal choice for reloaders of all skill levels:

- Ease of Use:The case feeder is designed with an intuitive user interface and simple setup process, making it easy to get started and use.

- Compatibility:It is compatible with most popular reloading presses and can be easily integrated into existing reloading setups.

- Efficiency:The case feeder automates the case feeding process, saving time and effort during reloading.

Case Feeder Design and Components: Hornady Lock N Load Case Feeder

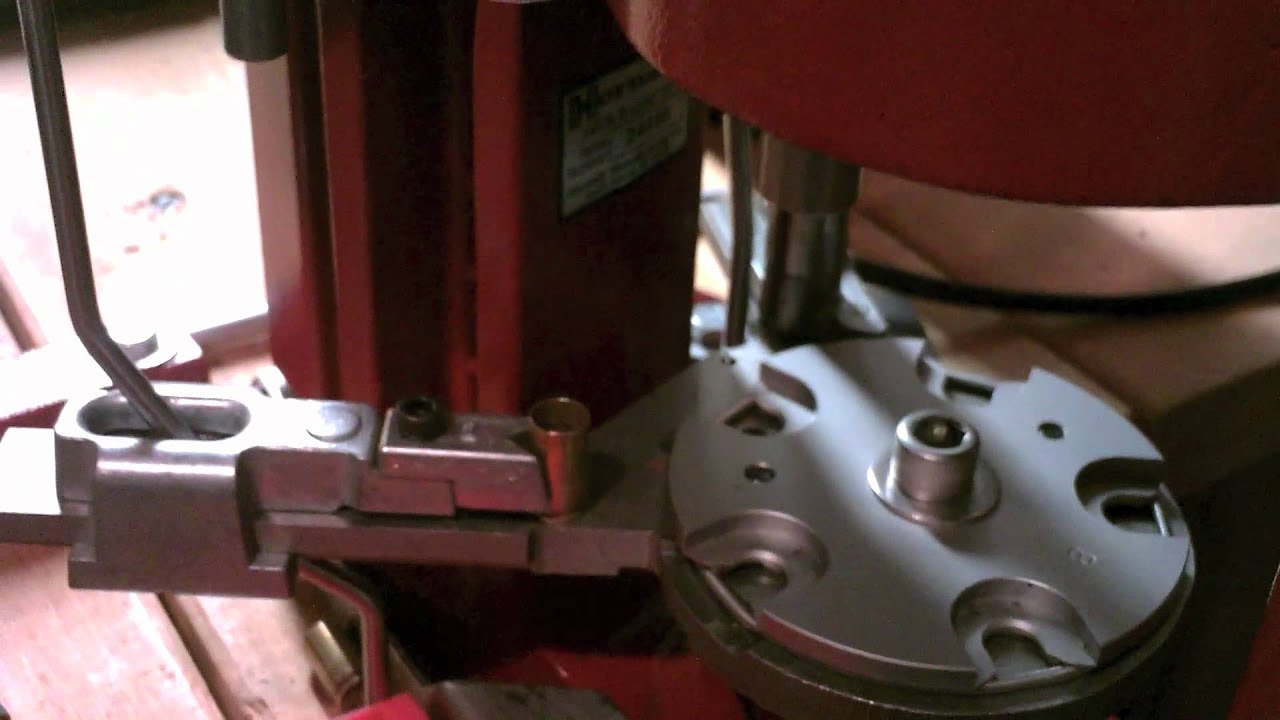

The Hornady Lock-N-Load Case Feeder is a versatile and reliable case feeding system designed to enhance the reloading process. Its innovative design and durable construction ensure smooth and efficient operation, minimizing manual intervention and maximizing productivity.The feeder comprises three main components: a hopper, a feed tube, and a collator.

The hopper, made of durable plastic, provides a spacious reservoir for holding a large quantity of cases. The feed tube, constructed from flexible rubber, gently guides the cases from the hopper to the collator. The collator, a precision-engineered mechanism, separates and aligns the cases, presenting them in the correct orientation for pickup by the shell plate.The

case feeder utilizes sensors and controls to ensure reliable operation. A proximity sensor detects the presence of cases in the feed tube, triggering the collator to advance and separate the next case. An adjustable vibration motor agitates the cases in the hopper, promoting consistent flow into the feed tube.

Additionally, a manual override switch allows for manual advancement of the collator in case of any irregularities.The materials used in the construction of the case feeder play a significant role in its durability and performance. The hopper’s plastic construction provides lightweight durability, while the flexible rubber feed tube ensures gentle handling of the cases.

The collator, made from precision-machined metal, guarantees accurate alignment and long-lasting performance.The combination of these design elements and materials results in a case feeder that delivers exceptional performance, minimizing case damage and ensuring a smooth and efficient reloading process.

Compatibility and Integration

The Hornady Lock-N-Load Case Feeder seamlessly integrates with various reloading presses and cartridge types, providing a convenient and efficient solution for reloaders.

It is compatible with a wide range of reloading presses, including single-stage, turret, and progressive presses. The feeder can be easily integrated into existing setups, eliminating the need for manual case feeding and significantly reducing reloading time.

Accessories and Modifications

For optimal performance, certain accessories or modifications may be necessary depending on the specific press and cartridge combination.

- Case Collator:For presses that do not have a built-in case collator, a separate collator may be required to align and orient the cases before they are fed into the press.

- Case Feeder Stand:A stand can elevate the feeder to the appropriate height for optimal operation with different press configurations.

- Adapter Plates:Adapter plates are available for specific presses and cartridges, ensuring a secure and stable connection between the feeder and the press.

Troubleshooting Compatibility Issues

If you encounter compatibility issues, here are some common troubleshooting steps:

- Check Adapter Plate:Ensure that the correct adapter plate is used for the specific press and cartridge combination.

- Adjust Feeder Height:The feeder should be positioned at the appropriate height to align with the press’s shell plate.

- Lubricate Case Collator:If cases are not feeding smoothly, try lubricating the case collator to reduce friction.

- Inspect Case Orientation:Verify that the cases are correctly oriented in the feeder tray and are being fed into the press in the proper direction.

Usage and Maintenance

The Hornady Lock-N-Load Case Feeder is a reliable and efficient tool for automating the case feeding process during reloading. Proper setup and maintenance are essential to ensure optimal performance and longevity of the feeder.

To set up the feeder, attach it to the top of the reloading press using the provided mounting bracket. Insert the case feed tube into the feeder and adjust the height of the tube so that the cases are properly aligned with the shell plate.

Adjust the tension of the feed tube by turning the adjustment knob until the cases are securely held in place but can still be easily fed into the shell plate.

Adjusting Feeder Settings

The feeder settings can be adjusted to accommodate different case sizes and types. To adjust the case length, loosen the set screw on the case length adjustment arm and slide the arm to the desired position. Tighten the set screw to secure the arm.

To adjust the case diameter, loosen the set screw on the case diameter adjustment arm and rotate the arm to the desired position. Tighten the set screw to secure the arm.

Maintenance

Regular maintenance is essential to ensure the feeder operates smoothly and efficiently. Clean the feeder periodically by removing any dust or debris that may accumulate. Lubricate the moving parts of the feeder, such as the feed tube and the adjustment arms, with a light oil or grease to reduce friction and wear.

Conclusive Thoughts

Whether you’re a seasoned reloader or just starting your journey, the Hornady Lock-N-Load Case Feeder is an investment that will elevate your reloading experience. Its exceptional performance, ease of use, and durability make it an indispensable tool for any serious reloader.