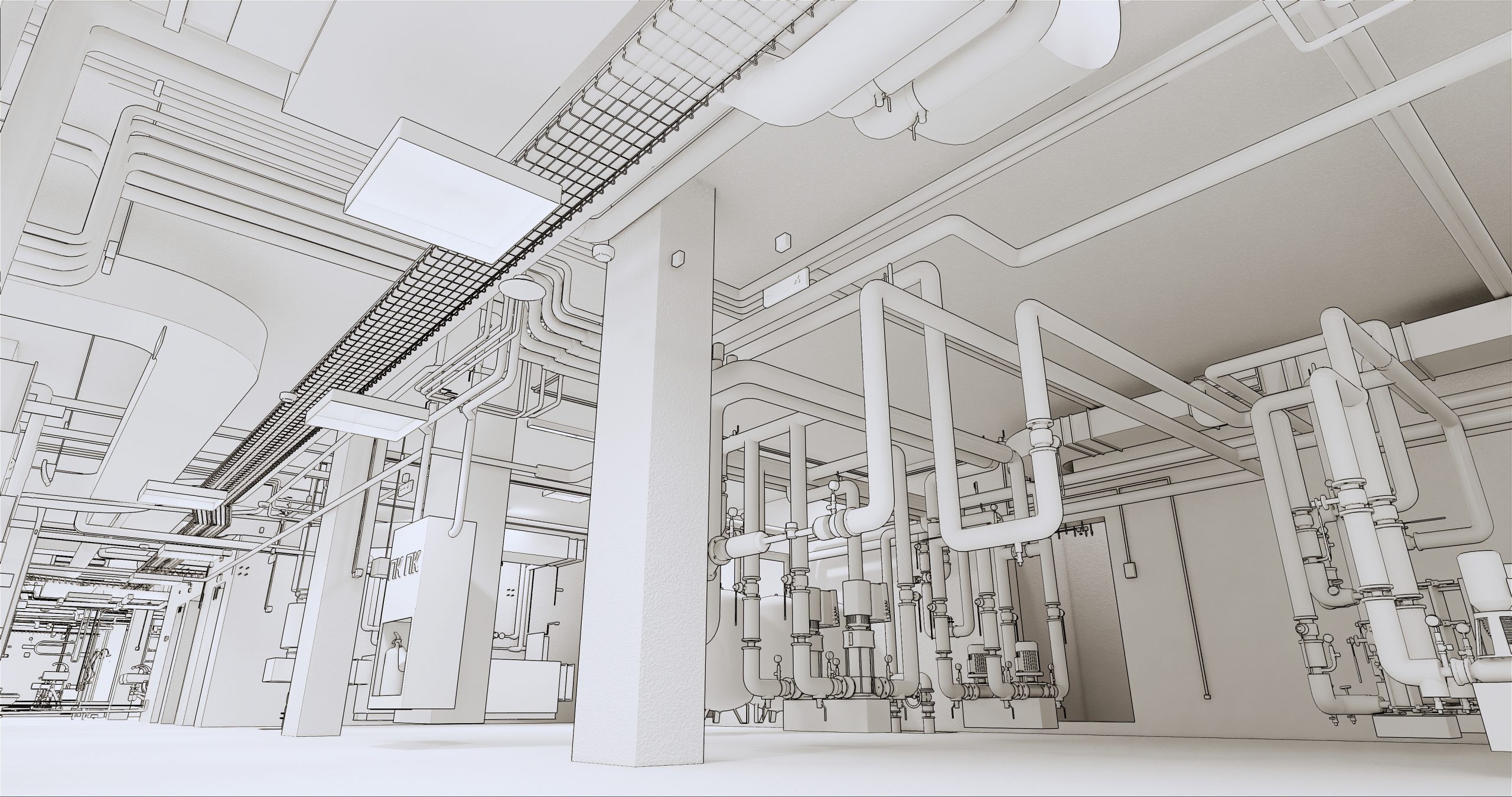

Mechanical electrical plumbing engineering, a multifaceted field encompassing mechanical, electrical, and plumbing systems, plays a crucial role in the design, construction, and maintenance of modern buildings and infrastructure. This comprehensive discipline ensures the seamless integration of these essential systems, creating efficient, safe, and sustainable environments.

Mechanical engineering systems, the backbone of MEP, involve the design, installation, and maintenance of HVAC equipment, pumps, and conveyors, ensuring optimal indoor air quality, temperature control, and fluid flow. Electrical engineering systems, equally vital, focus on lighting, power distribution, and control systems, providing reliable and efficient electrical infrastructure.

Plumbing engineering systems, the third pillar of MEP, encompass water supply, drainage, and waste disposal, ensuring the health and safety of building occupants.

Mechanical Engineering Systems

Mechanical engineering is a discipline that applies the principles of physics and materials science to design, analyze, manufacture, and maintain mechanical systems. In the context of MEP systems, mechanical engineering plays a crucial role in ensuring the efficient and reliable operation of various mechanical components and systems.

HVAC Equipment

HVAC (heating, ventilation, and air conditioning) systems are essential for maintaining comfortable indoor environments. Mechanical engineers design and specify HVAC equipment, such as air handling units, chillers, boilers, and ductwork, to meet the specific heating, cooling, and ventilation requirements of a building.

Pumps

Pumps are used to move fluids throughout MEP systems. Mechanical engineers select and design pumps based on the flow rate, pressure, and fluid properties required for the specific application. Pumps can be used for a variety of purposes, such as circulating water in a cooling system or transporting wastewater.

Conveyors

Conveyors are used to transport materials from one location to another. Mechanical engineers design and specify conveyors based on the type of material being transported, the required capacity, and the distance and elevation changes involved.

Role of Mechanical Engineers

Mechanical engineers play a vital role in the design, installation, and maintenance of MEP systems. They work closely with other engineering disciplines, such as electrical and plumbing engineers, to ensure that all systems are integrated and operate efficiently. Mechanical engineers also perform energy audits and retrofits to improve the efficiency of existing MEP systems.

MEP System Integration: Mechanical Electrical Plumbing Engineering

Integrating mechanical, electrical, and plumbing (MEP) systems is crucial in MEP design, ensuring optimal building performance, efficiency, and occupant comfort. By coordinating these systems, engineers can create cohesive and functional environments that meet specific project requirements.

Challenges of MEP System Integration

Integrating MEP systems presents challenges that require careful planning and coordination. These include:

- Space Constraints:Coordinating the placement of MEP equipment and ductwork within limited building spaces can be challenging.

- System Interdependencies:MEP systems are interdependent, affecting each other’s performance and efficiency.

- Code Compliance:MEP systems must adhere to various building codes and regulations, which can vary across jurisdictions.

Benefits of MEP System Integration

Despite the challenges, MEP system integration offers numerous benefits:

- Improved Building Performance:Integrated systems optimize energy efficiency, reduce operating costs, and enhance occupant comfort.

- Reduced Construction Costs:Coordinated design and installation can minimize material waste and labor costs.

- Increased Flexibility:Integrated systems allow for easier modifications and upgrades in the future.

Examples of Successful MEP System Integration Projects, Mechanical electrical plumbing engineering

Numerous successful MEP system integration projects showcase the benefits of this approach:

- Burj Khalifa, Dubai:The world’s tallest building features an advanced MEP system that optimizes energy efficiency and provides a comfortable environment for occupants.

- Shanghai Tower, China:This iconic skyscraper incorporates sustainable MEP systems that minimize energy consumption and reduce environmental impact.

- One World Trade Center, New York City:The LEED Platinum-certified building showcases innovative MEP systems that enhance occupant comfort and safety.

Last Recap

The integration of mechanical, electrical, and plumbing systems is paramount in MEP design, presenting both challenges and opportunities. By working collaboratively, engineers can optimize system performance, reduce energy consumption, and enhance occupant comfort. Successful MEP system integration projects, such as the Burj Khalifa and the Shanghai Tower, showcase the transformative power of this interdisciplinary approach.