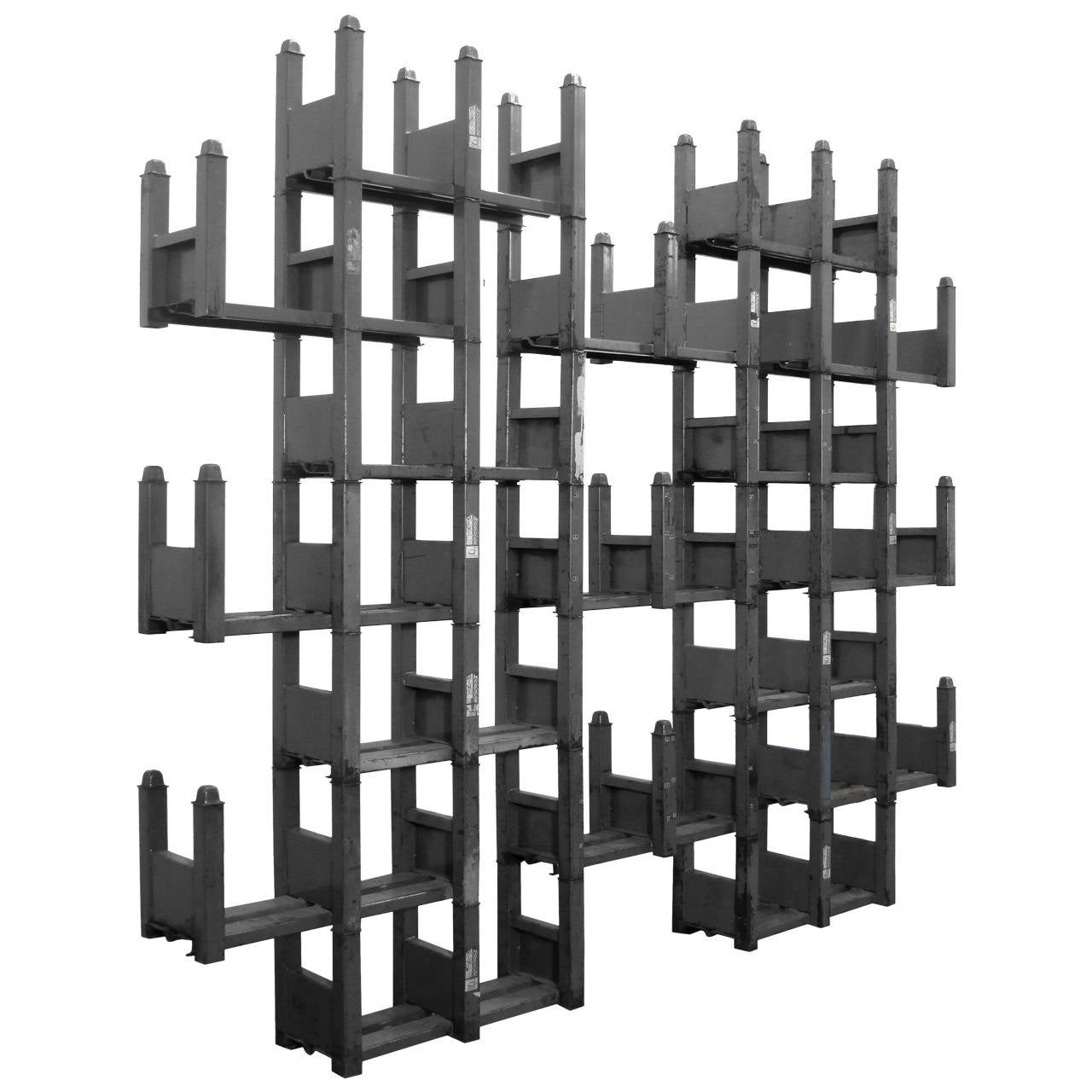

Discover the transformative power of modular industrial shelving, a versatile storage solution that empowers businesses to maximize space, enhance efficiency, and adapt to evolving storage needs. From warehouses to factories and distribution centers, modular shelving offers a customizable and robust approach to organizing and storing a wide range of materials and equipment.

This innovative shelving system is designed to meet the unique challenges of industrial environments, providing exceptional durability, weight capacity, and ease of assembly. Dive into the world of modular industrial shelving and unlock the potential for streamlined operations and optimized storage.

Features and Benefits of Modular Industrial Shelving

Modular industrial shelving systems offer numerous advantages over traditional fixed shelving. Their versatility and adaptability make them ideal for a wide range of storage needs in various industrial settings.

One key benefit of modular shelving is its ability to be customized to meet specific storage requirements. The individual components, such as shelves, uprights, and accessories, can be easily configured to accommodate different item sizes, weights, and shapes. This flexibility allows for efficient use of space and ensures optimal storage capacity.

Customization and Adaptability

- Modular shelving can be tailored to fit specific dimensions and layouts, making it suitable for various storage spaces.

- Shelves can be adjusted vertically to accommodate items of varying heights, maximizing vertical storage capacity.

- Accessories such as dividers, drawers, and bins can be added to enhance organization and accessibility.

Benefits in Industrial Settings, Modular industrial shelving

Modular industrial shelving provides numerous benefits in warehouses, factories, and distribution centers:

- Improved space utilization:The ability to customize shelving configurations allows for optimal space utilization, maximizing storage capacity without compromising accessibility.

- Increased efficiency:Modular shelving systems facilitate efficient inventory management and order fulfillment, reducing picking and retrieval times.

- Enhanced safety:Sturdy construction and adjustable components ensure stability and safety, minimizing the risk of accidents.

Types and Applications of Modular Industrial Shelving

Modular industrial shelving systems offer a versatile solution for various storage needs. They come in different types, each designed for specific applications and weight capacities.

Boltless Shelving

Boltless shelving, also known as clip shelving, is a type of shelving that can be assembled without using any bolts or tools. The shelves are held in place by clips that fit into slots in the uprights. This type of shelving is easy to assemble and disassemble, making it a good choice for temporary storage or for applications where frequent reconfiguration is required.

Boltless shelving is typically made of steel or aluminum and can support moderate weight loads.

Rivet Shelving

Rivet shelving is a type of shelving that is assembled using rivets. The shelves are attached to the uprights using rivets, which are permanent fasteners. This type of shelving is more durable than boltless shelving and can support heavier weight loads.

Rivet shelving is typically made of steel and is often used in industrial and commercial applications.

Welded Shelving

Welded shelving is a type of shelving that is assembled by welding the shelves to the uprights. This type of shelving is the most durable and can support the heaviest weight loads. Welded shelving is typically made of steel and is used in heavy-duty industrial applications.

Applications of Modular Industrial Shelving

The different types of modular industrial shelving are used in a variety of applications, depending on their weight capacity, durability, and ease of assembly.Boltless shelving is often used in retail stores, offices, and other commercial applications where frequent reconfiguration is required.

Rivet shelving is often used in warehouses, distribution centers, and other industrial applications where durability is important. Welded shelving is often used in heavy-duty industrial applications, such as manufacturing plants and warehouses.

Design Considerations for Modular Industrial Shelving

Modular industrial shelving offers flexibility and customization to meet specific storage requirements. To design an effective shelving system, several key considerations must be taken into account:

Height, Depth, and Weight Capacity

The height and depth of the shelving units should align with the items being stored and the available space. Shelves should be tall enough to accommodate the items without compromising stability. The depth should allow for easy access to items without overcrowding.

Weight capacity is crucial to ensure the shelving can safely support the intended load. It is essential to consider the weight of the stored items and the maximum weight capacity of the shelves.

Shelving Materials

The choice of shelving materials depends on the intended use and environmental conditions. Steel shelving is durable, strong, and resistant to corrosion, making it suitable for heavy-duty applications. Plastic shelving is lightweight, corrosion-resistant, and easy to clean, ideal for storing lighter items in environments where hygiene is a priority.

Wire shelving provides good airflow and visibility, making it suitable for storing bulky or irregular-shaped items.

Accessories

Accessories such as dividers, shelves, and drawers can enhance the storage capacity and functionality of modular industrial shelving. Dividers help organize and separate items within shelves, while additional shelves increase storage space. Drawers provide enclosed storage for sensitive items or items that require easy access.

Choosing the right accessories can optimize the shelving system to meet specific storage needs.

Installation and Maintenance of Modular Industrial Shelving

Installing and maintaining modular industrial shelving is crucial for ensuring its safety and longevity. Proper installation involves following specific steps and adhering to safety precautions. Regular maintenance checks help identify and address potential issues, preventing accidents and extending the system’s lifespan.

Installation

Before installation, ensure the work area is clear and level. Gather the necessary tools and components, including the shelving units, posts, beams, and any accessories. Wear appropriate safety gear such as gloves and safety glasses.1.

-

-*Plan the layout

Determine the desired shelving configuration and mark the floor accordingly.

- 2.

- 3.

- 4.

- 5.

-*Assemble the posts

Connect the posts to the base plates and secure them using bolts.

-*Install the beams

Place the beams onto the posts and secure them using clips or bolts.

-*Add shelves

Slide the shelves onto the beams and adjust them to the desired height.

-*Check for stability

Ensure the shelving system is level and stable by applying weight to the shelves.

Maintenance

Regular maintenance is essential to maintain the integrity of modular industrial shelving.

-

-*Inspect regularly

Inspect the shelving system periodically for any signs of damage, corrosion, or loose components.

-*Tighten bolts

Check and tighten any loose bolts or screws to ensure stability.

-*Clean the shelves

Regularly clean the shelves to remove dust and debris that could affect load capacity.

-*Check load capacity

Do not overload the shelves. Ensure the weight distributed on the shelves is within the specified load capacity.

-*Repair promptly

If any damage or issues are identified, repair or replace the affected components promptly to prevent further deterioration.

Troubleshooting

-

-*Sagging shelves

Check for overloaded shelves or loose beams. Adjust the beams or redistribute the weight.

-*Wobbling shelves

Inspect the posts and base plates for stability. Tighten any loose bolts or screws.

-*Corrosion

Clean the affected areas and apply anti-corrosion coating to prevent further damage.

-*Damaged components

Replace any damaged components, such as shelves, beams, or posts, to ensure safety.

Last Point

In conclusion, modular industrial shelving emerges as a game-changer for businesses seeking to optimize their storage capabilities. Its adaptability, durability, and ease of maintenance make it an ideal choice for a wide range of industrial settings. By embracing modular shelving solutions, businesses can transform their storage operations, enhance productivity, and gain a competitive edge in the ever-evolving industrial landscape.